SMT Consulting SMT Process Experts

Technical Solutions for Risk Assessment, Management and Process Improvement

ITM Consulting provides strategic management and technical solutions to boost your performance. Count on us to help you earn a competitive edge as you comprehend your unique market position and scope.

SMT Consulting SMT Process Experts

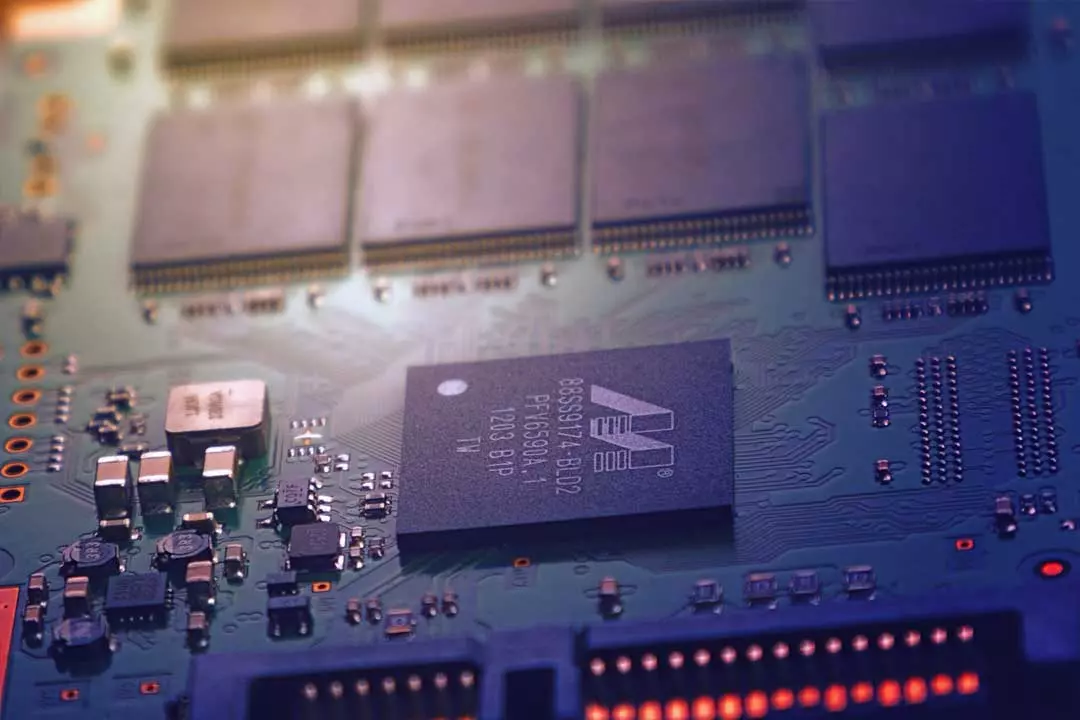

Streamline Your Assembly Line or Process With Our Help

ITM Consulting in Springfield, Tennessee provides strategic management and technical solutions to boost your performance. Count on us to help you earn a competitive edge as you comprehend your unique market position and scope.

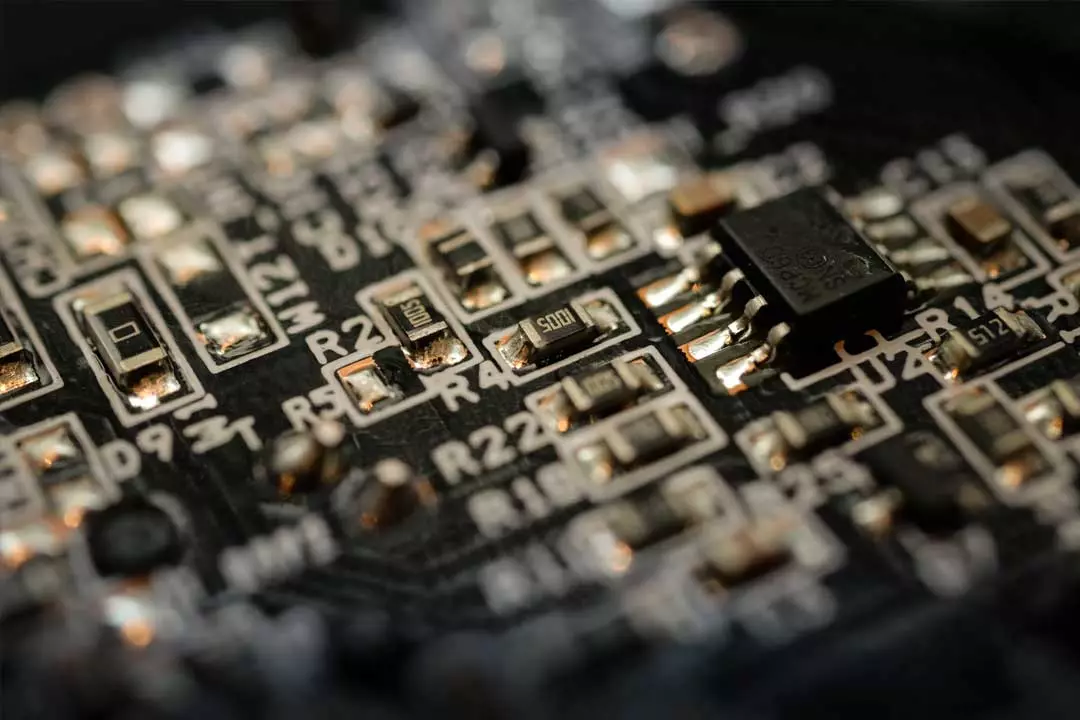

- Assembly Process Evaluation and Troubleshooting

- Equipment and Materials Benchmarking and Development

- Equipment Evaluation and Selection for Contract Assembly and OEMs

- Risk Assessment and Management Consulting

- PCB Fabrication Source Qualification

- Process Certification

- Process Setup and Development

- Retained Consulting Services

- Lead-Free and No-Clean Roadmapping and Implementation

- Outsourcing SMT to Contract Assembly

- SMT Design for Manufacturability

- SMT Manufacturing

- Solder Paste Evaluation

- Stencil Printing and Inspection

- Wave and Selective Soldering

- Reflow Soldering

Business Services

- Marketing Consulting Services

- Merger and Acquisition Evaluation

- Outsourcing Services

- Process Dispute Mediation and Expert Witness

- Sales and Marketing Analysis

Custom programs and services can also be developed to meet specific needs and keep pace with the ever-changing electronics industry.

About ITM Consulting

Who We Are

At ITM Consulting, we help you take on new challenges by showing you various principles that are present in today’s issues. We work hard to earn your trust and respect by creating excellent technical and business solutions unique to you.

Clients

BOARD TALK

BOARD TALK